Video Url

WINDMILL WIND AND SOLAR ENERGY UPGRADE:

Wind turbines work on a simple principle: instead of using electricity to make wind—like a fan—wind turbines use wind to make electricity. Wind turns the propeller-like blades of a turbine around a rotor, which spins a generator, which creates electricity.

Explore a Wind Turbine

To see how a wind turbine works, click on the image for a demonstration.

Wind is a form of solar energy caused by a combination of three concurrent events:

- The sun unevenly heating the atmosphere

- Irregularities of the earth's surface

- The rotation of the earth.

Wind flow patterns and speeds vary greatly across the United States and are modified by bodies of water, vegetation, and differences in terrain. Humans use this wind flow, or motion energy, for many purposes: sailing, flying a kite, and even generating electricity.

The terms "wind energy" and "wind power" both describe the process by which the wind is used to generate mechanical power or electricity. This mechanical power can be used for specific tasks (such as grinding grain or pumping water) or a generator can convert this mechanical power into electricity.

A wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades, which work like an airplane wing or helicopter rotor blade. When wind flows across the blade, the air pressure on one side of the blade decreases. The difference in air pressure across the two sides of the blade creates both lift and drag. The force of the lift is stronger than the drag and this causes the rotor to spin. The rotor connects to the generator, either directly (if it’s a direct drive turbine) or through a shaft and a series of gears (a gearbox) that speed up the rotation and allow for a physically smaller generator. This translation of aerodynamic force to rotation of a generator creates electricity.

Types of Wind Turbines

The majority of wind turbines fall into two basic types:

HORIZONTAL-AXIS TURBINES

VERTICAL-AXIS TURBINES

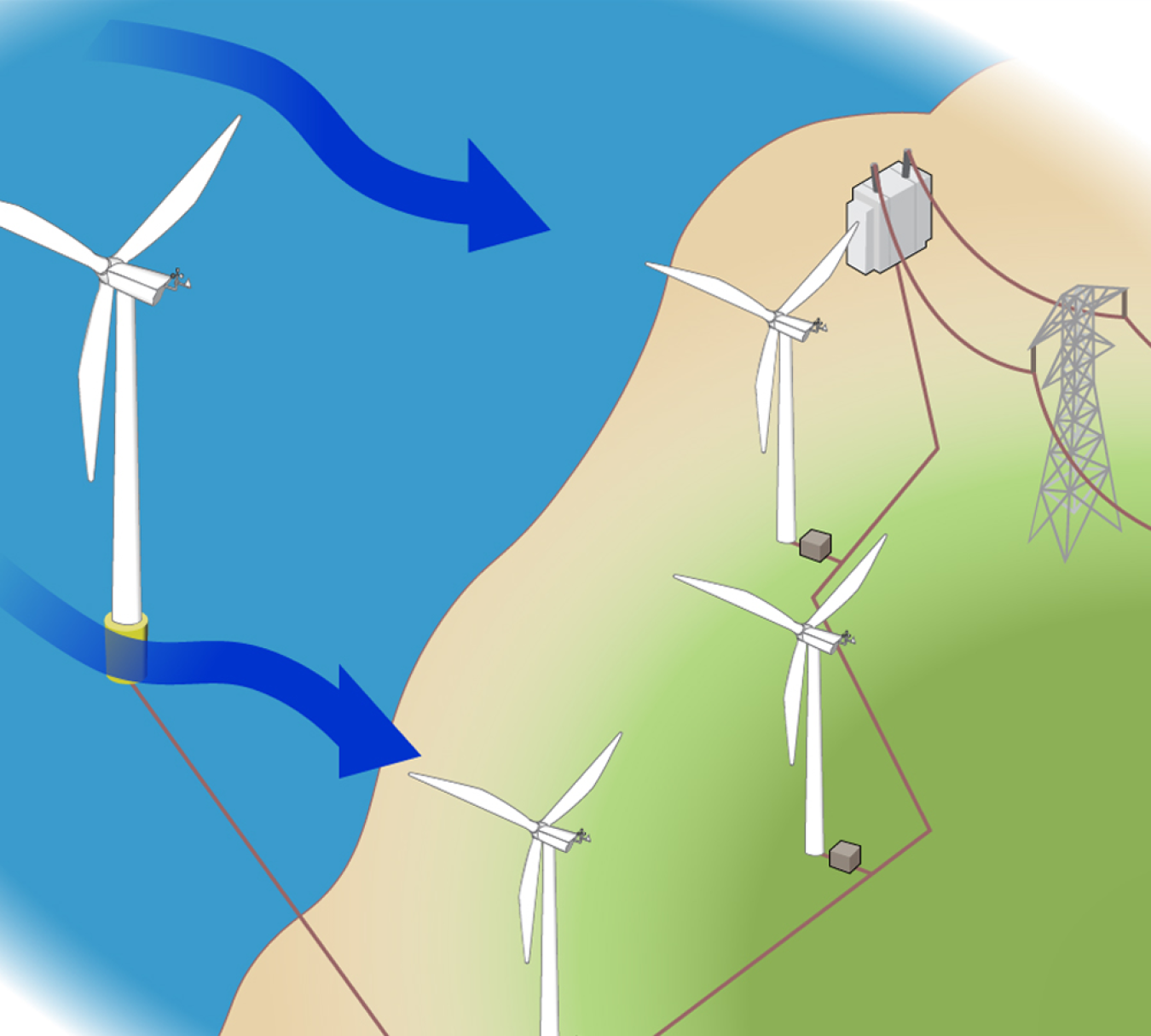

Wind turbines can be built on land or offshore in large bodies of water like oceans and lakes. The U.S. Department of Energy is currently funding projects to facilitate offshore wind deployment in U.S. waters.

LAND-BASED WIND

OFFSHORE WIND

DISTRIBUTED WIND

Interested in wind energy? The Small Wind Guidebook helps homeowners, ranchers, and small businesses decide if wind energy can work for them.

More wind energy resources can be found at WINDExchange, which has lesson plans, websites, and videos for K-12 students, as well as information about the Wind for Schools Project and the Collegiate Wind Competition.

ENERGY 101: GENERATING CLEAN ELECTRICITY FROM THE WIND

This video highlights the basic principles at work in wind turbines and illustrates how the various components work to capture and convert wind energy to electricity. See the text version.

U.S. Department of Energy

Find out more about wind energy by visiting the Wind Energy Technologies Office web page or browsing the office's funded activities.

The Power of Wind

Wind turbines harness the wind—a clean, free, and widely available renewable energy source—to generate electric power.

The animation below is interactive. You can start and stop the turbine’s movement, hover over parts to see their description, and use the icons in the lower right corner of the animation to switch views.

A wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades, which work like an airplane wing or helicopter rotor blade. When wind flows across the blade, the air pressure on one side of the blade decreases. The difference in air pressure across the two sides of the blade creates both lift and drag. The force of the lift is stronger than the drag and this causes the rotor to spin. The rotor connects to the generator, either directly (if it’s a direct drive turbine) or through a shaft and a series of gears (a gearbox) that speed up the rotation and allow for a physically smaller generator. This translation of aerodynamic force to the rotation of a generator creates electricity.

THE PORTABLE WINDMILL WIND AND SOLAR ENERGY THAT MUST BE UPGRADED:

All its construction panels are made of solar panels to produce daytime solar energy.

The rotar blades are run by wind day and night.

The portable windmill connected to vehicles for transportation, the impact of wind by a speeding vehicle drives the rotar blades.

Small Wind Electric System Components

A wind electric system is made up of a wind turbine mounted on a tower to provide better access to stronger winds. In addition to the turbine and tower, small wind electric systems also require balance-of-system components.

Turbines

Most small wind turbines manufactured today are horizontal-axis, upwind machines that have two or three blades. These blades are usually made of a composite material, such as fiberglass.

The turbine's frame is the structure onto which the rotor, generator, and tail are attached. The amount of energy a turbine will produce is determined primarily by the diameter of its rotor. The diameter of the rotor defines its "swept area," or the quantity of wind intercepted by the turbine. The tail keeps the turbine facing into the wind.

Towers

Because wind speeds increase with height, a small wind turbine is mounted on a tower. In general, the higher the tower, the more power the wind system can produce.

Most turbine manufacturers provide wind energy system packages that include towers. There are two basic types of towers: self-supporting (free-standing) and guyed (supported with wires). There are also tilt-down versions of each tower type.

While tilt-down towers are more expensive, they offer an easy way to perform maintenance. Tilt-down towers can also be lowered to the ground during hazardous weather such as hurricanes.

Balance of System Components

The balance-of-system parts you'll need for a small wind electric system -- those in addition to the wind turbine and the tower -- will depend on your application. For example, the parts required for a water pumping system will be much different from what you need for a residential application.

The balance-of-system parts required will also depend on whether your system is grid-connected, stand-alone, or hybrid.

Manufacturers and installers can provide you with a system package that includes all the parts you need for your particular application. For a residential grid-connected application, the balance-of-system parts may include the following:

- A controller

- Storage batteries

- An inverter (power conditioning unit)

- Wiring

- Electrical disconnect switch

- Grounding system

- Foundation for the tower.

Wind power is the fastest growing source of energy in the world -- efficient, cost effective, and non-polluting.